Content of this post about AI and thermosets:

Today’s challenges of the manufacturing industry

Sustainable materials and production processes

The future role of reinforced plastics

Best practices: What are thermosets already successfully used for?

Example 1: Pump housing from the automotive sector (Bakelite company)

Example 2: Printed circuit board (Raschig company)

Interaction of AI and thermosets

Today’s challenges of the manufacturing industry

Today’s challenges to the manufacturing industry and the manufacturing sector are numerous and diverse.

On the one hand, the sensitized awareness of end customers for topics such as sustainability and new political laws, such as changing production standards due to the Green Deal, influences the requirements for the production process.

These changes in the market economy create a field of tension that affects all manufacturing industries and their suppliers and manufacturers:

- The trend towards sustainable end products and manufacturing enormously pressures all companies along the vertical value chain.

- Development and use of sustainable and biodegradable plastics

- The shortage of skilled labor combined with higher demands on production – higher product quality and lower scrap rates – makes smart manufacturing and AI solutions essential in the future.

- The disruption of existing technologies, such as the replacement of the combustion engine by e-mobility, requires innovative components and plastics that can cope with the new technologies.

Conclusion: The current evolution of the manufacturing industry towards Industry 4.0 poses extreme challenges for processors, manufacturers, and users.

Sustainable materials and production processes

As the initial situation outlined above shows, many established industries face new challenges. As a result, previous production must be rethought, and the materials used adapted to future requirements. Primarily, the following two topics are emerging:

The following two main topics emerge:

- On the one hand, the use of sustainable materials that complement the use of new technologies such as e-mobility.

- Optimized manufacturing processes lead to better products and lower scrap rates through AI and smart manufacturing.

The future role of reinforced plastics

Composites such as thermosets bundle all the properties and advantages that the materials “of tomorrow” will have to exhibit. Compared with conventional materials in particular, thermosets can score points in the following areas:

- Considerable design flexibility

- Resistance to mechanical effects such as corrosion, deterioration, fatigue and high temperatures

These properties make thermosets interesting for many industries and applications.

Because of the ever-increasing importance of thermosets, the next section will give you a brief but informative introduction to the world of this plastic.

What are thermosets?

Thermosets, also known as duromers, are particularly hard/stiff and durable polymer materials known for their excellent thermomechanical properties, for example.

Thermosets are formed by chemical crosslinking of polymer molecules. During processing (e.g. injection molding), the material forms a three-dimensional, close-meshed molecular network that is highly resistant to any changes in shape or size after curing.

Once thermosets have cured, the plastic can no longer be melted and subsequently deformed. This characteristic fundamentally distinguishes thermosets from thermoplastics.

Thermosets are ideal materials for many industrial applications where heat deflection temperature/dimensional stability plays an important role: for example, in engine compartments, safety helmets, car body parts, household appliances, insulation of electrical components or for aircraft parts.

Advantages of thermosets?

In contrast to thermoplastics, whose molecular chains are held together solely by physical bonding forces, in thermosets it is the chemical bonds of the molecular network that provide the high resistance to all types of stress.

Thermosets are resistant to heat, chemicals, deformation, and wear. In addition, they exhibit excellent electrical insulation properties. Therefore, thermosets are suitable for various industrial and commercial applications. Therefore, thermosets are suitable for a variety of industrial and commercial applications.

Thermoset molding compounds can be processed by manufacturing methods such as injection molding, injection compression molding or compression molding. As with thermoplastics, there are virtually no limits to the shape and geometry of components. Subsequent mechanical processing steps are required. Thermosets are superior to thermoplastics in terms of the dimensional tolerances that can be achieved.

- Design flexibility

- Lighter in weight and more cost-effective than components made of metals

- Excellent electrical insulation properties

- Excellent strength-to-weight ratio

- Weather and water-resistant

- Fire and heat resistance at high temperatures

- Dimensional stability under extreme loads

Best Practices: What are thermosets already being used for successfully?

This presents an excellent opportunity for the plastics industry. Because by using thermoset materials, it is possible to respond effectively to future market requirements and to exploit the advantages of this plastic,

- the low weight compared to metal

- the heat resistance,

- the cost-effective production in known/proven processes,

- the dimensional stability (even under high loads) and

- the ability to shape the material into the required form,

can be used.

However, to take advantage of the positive effects of this plastic, a suitable control mechanism that overcomes certain processing pieces is necessary.

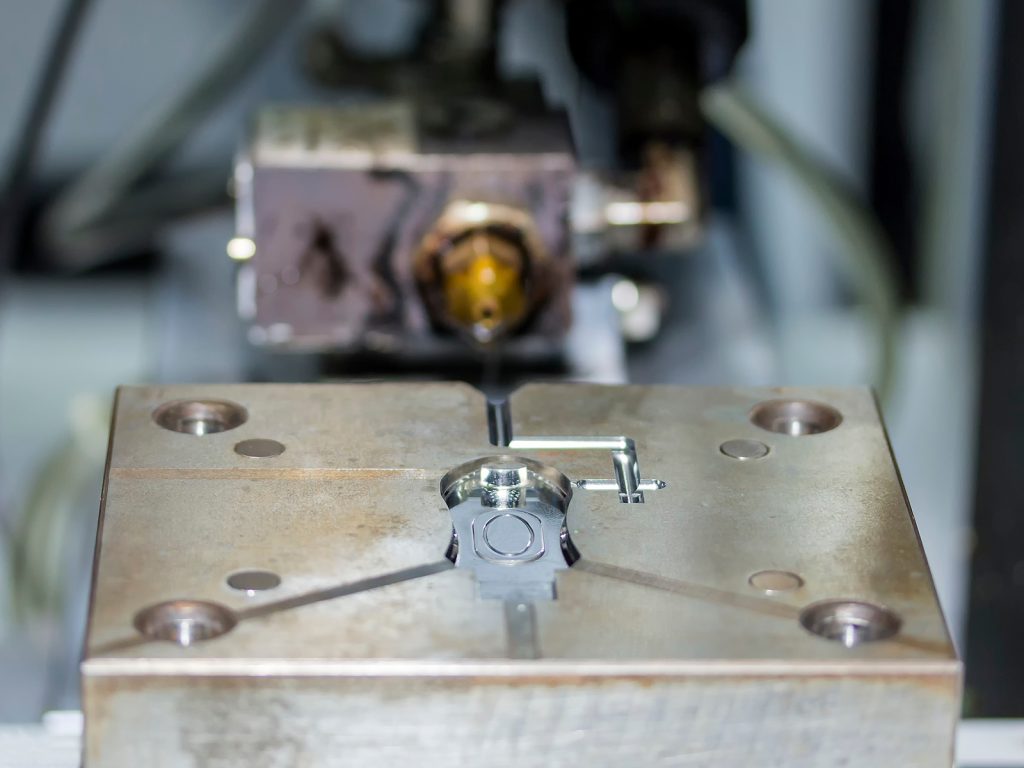

Example 1: Pump housing from the automotive sector (Bakelite company)

The component from the Bakelite company is injection molded from a phenolic resin compound reinforced with glass fiber. Due to its use in the automotive sector, it has to withstand temperatures from minus 40° C to plus 150° C. It is constantly exposed to aggressive water. It is constantly in contact with an aggressive water-glycol mixture. At the same time, it must be dimensionally stable to permanently withstand the vibrations and forces in the engine.

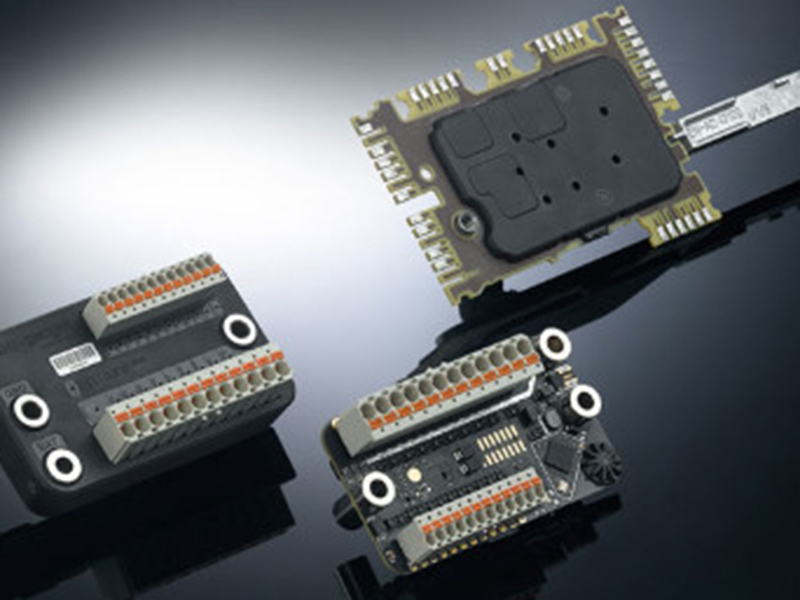

Example 2: Printed circuit board (Raschig company)

To function in a permanently stable manner, the printed circuit boards (PCB), which are equipped with many sensitive components (chips, capacitors, coils), must be effectively protected from environmental influences. The low temperatures during overmolding and the low viscosity allow very low pressures, which is why the components do not suffer any damage. This is not possible with thermoplastics.

In addition, the overmolded elements are so robust that they can be screwed together without additional metal bushings.

Interplay between AI and thermosets

From raw material to finished product: thermoset materials are exposed to various environmental and production influences on their way to the end product. This variance can hurt the quality and stability of the end product.

Especially during production, the temperature and thermal insulation of the production material must be constantly monitored. This is the only way to guarantee low scrap rates and a final product of stable quality.

Since thermoset materials are susceptible to changes in production, it is almost impossible for non-expert personnel to produce high-quality end products consistently. .

Given the increasing shortage of skilled workers and limited understanding of the processing properties of thermosets, working with the plastic presents challenges for many companies. New technologies are needed to unleash the benefits of thermosets in the future to ensure consistent, high-quality production.

Using AI in the processing of thermosets.

In the fabrication of thermoset components, the use of artificial intelligence (AI) is leading to significant production benefits.

The interaction of sensors, AI software and tools makes the “black box” of thermoset manufacturing transparent for the first time. The newly acquired information can be used to control production cycles and make necessary adjustments if the need arises.

sensXPERT: The future of thermoset production

How can you produce high-quality thermoset components quickly and with consistent quality? With sensXPERT.

sensXPERT combines real-time material data from your mold with advanced machine learning software to analyze material behavior.

The technology enables you to continuously optimize your process, increasing your production efficiency by up to 30 percent.

The sensors in the mold provide real-time insights and create transparency to respond to material deviations and reduce scrap.

sensXPERT enables direct quality control of each molded part during production. Since sensXPERT works on a previously tested data basis, quality can be documented without gaps even with adjusted process control.

Your advantages when you use sensXPERT in your production:

- Increase your production efficiency by up to 30%.

- Use of a technology that enables you to continuously optimize your processes based on the sensor-supported machine, tool, and material data in real-time

- Inspection capability of the end product

- Real-time access to material character data will help you form better parts faster and at a lower cost.